Monoblock for filling wine

GAI products are exported in five continents (export represents 80% of the turnover) by an extended network of retailers and importers, which supply immediate technical assistance on site and spare parts in the long term.

GAI Macchine Imbottigliatrici S.p.a. has a spare parts warehouse with 25.000 items, that can be PROMPTLY DELIVERED. This enables us to rapidly assist our customers.

GAI Macchine Imbottigliatrici S.p.a. continuously updates and trains all technicians' retailers in Italy and abroad. Technical expertise is an essential precondition in order to be a reseller of GAI Macchine Imbottigliatrici S.p.a.

A product manufactured by GAI Macchine Imbottigliatrici S.p.a. is robust and reliable. Therefore, it is "guaranteed for life" and has a long-term value with a contained depreciation. For that reason, we believe that our clients are aware of buying easily saleable products with a very high gain in case of a sale of used products.

1. Rinsing

The bottles are gripped around the neck by a clamp, and rapidly turned upside-down by means of a rack and pinion system. The speed of this system enables longer cycles with the same number of clamps. The nozzle penetrates the bottle neck by 70mm as per machine model; this depth prevents any interference between the injected water and the backflow. The injected water must be sterilized by microfiltration. As an alternative, the water can be ozonized, which will also perform a sterilizing action.

The rinsing liquid is recovered in a closed circuit, keeping the machine dry during the normal working conditions.

Bottles can also be “seasoned” by recirculating the appropriate product. This means that a bactericidal liquid can be used to completely sterilize the inside of the rinser, using the dummy bottles supplied with the machine.

2. De-areation

A high vacuum pump removes approximately 90% of the air from the bottle, after which the bottle is filled with an inert gas. Normally nitrogen is used, but CO2 or a mixture of nitrogen and CO2 can also be used.

Air suction and neutral gas injection only take place if a bottle is present.

Thanks to our special (patented) filling valves, the same atmosphere is created in the filler bowl as in the bottle.

De-aeration reduces average oxygen absorption on filling from an average of 0.6 to 0.09 mg per liter of wine, and the amount of oxygen contained in the head space is reduced from 0.1 to 0.08 mg.

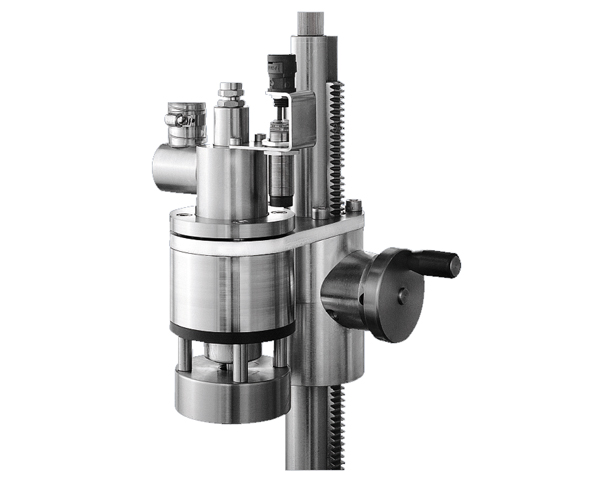

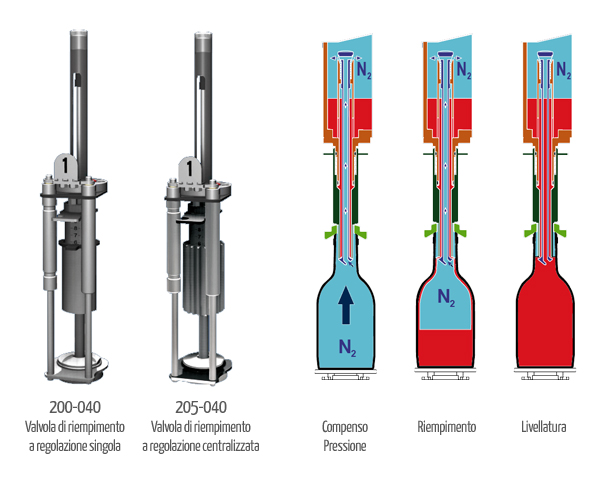

3. Filling

The (patented) filling valves shut off both the flow of wine and the gas backflow; the filler tank is therefore only in contact with the atmosphere created in the bottle, benefiting both the oxidation and the sterility.

The filler valves can operate by gravity or light vacuum.

The advantages of light vacuum are as follows:

- improved priming of the filling

- guaranteed absence of dripping, even if the bottom seal is not in perfect condition.

With our valve there are no contra-indications to the use of a light vacuum: as no air is introduced into the tank, there will be no oxidation, contamination or reduction in aromas.

The filling level can be adjusted individually (from 30 to 80 mm from the mouth rim valve 200-040) or centralized (from 30 to 90 mm from the mouth rim valve 205-040). The opening of the valve for sterilization can also be centralized or set individually. Wine is fed from below so that it arrives without oxidation, and above-all so that the tank - which has a conical bottom with drainage in the middle - can be emptied completely. The tank’s side wall can be thin or thick; in this case it is fully machine tool-worked with a specular inside finish to make it easy to clean and sterilize. The height of the filler can be adjusted manually or electrically. The bottle-raising pistons are mechanically-operated with spring thrust and cam return. The filler rotates on a bearing system.

The monobloc’s main greasing points are centralized.

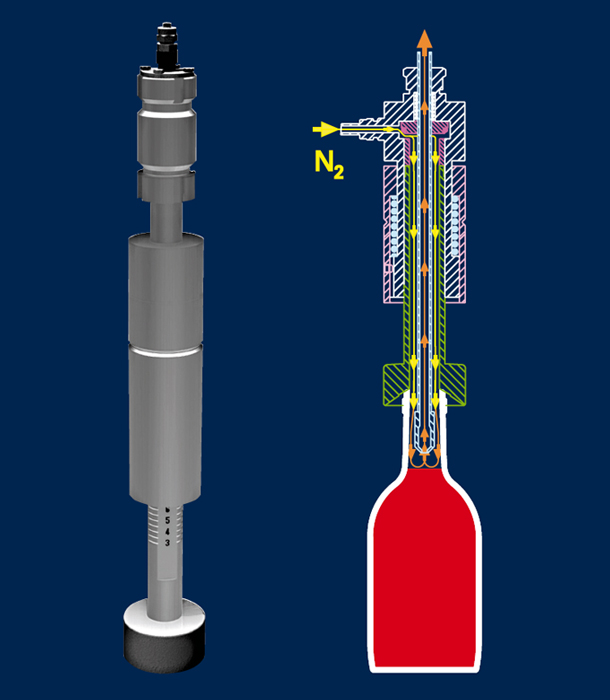

4. Injection gas

This is a very important operation on account of its many functions:

IT DRASTICALLY REDUCES OXIDATION: With a filling level of 60 mm and a 45 mm cork, the oxygen is reduced from 1.4 mg to 0.25 mg per liter of wine.

IT COMBATS CORK LEAKAGE: The CO2 dissolves into the wine, eliminating the pressure between the wine and the cork (using CO2).

THE GAS INJECTOR CAN ALSO BE USED TO CONTROL THE FILLING LEVEL: The standard level tolerance is reduced from ± 1 mm to ± 0.5 mm. The gas injector is supplied with a dummy bottle, making it easy to sterilize.

5. Corking vacuum

Four stainless steel prismatic guide studs close the cork to a diameter of 16 mm. Extreme care is taken over the making of the corking head, with a roughness of less than 0.05 microns on the surfaces in contact with the cork.

The compression of the cork is slow (105°), with fast fitting of the cork (53°).

The studs box is easily extractable to simplify the maintenance and the cleaning operations.

All models are standard fitted with vacuum corking.

The advantages of this system are as follows:

1) no pressure is created in the bottle when the cork is inserted

2) the oxygen trapped between the wine and the cork is further reduced from 0.25 to 0.08 mg per liter (with a 0.75 lt bottle, filling level 60, and 45 mm cork).

AS AN ALTERNATIVE, provision can be made for types of closure other than corks.

6. Screw cap

The caps are fed by a vibrator, which is stopped by a photocell when the cap channel is full. On the 4292, the caps are distributed straight onto the bottle in the star preceding the closure head.

On the 4295 (see photo), the following operations are performed:

1) injection of inert gas into the bottle neck.

2) washing of the caps with inert gas.

3) introduction of the caps onto the neck of the bottle by pneumatic piston.

The advantages of this system in terms of oxidation are shown in the table on page 36.

The cap closure device has 4 rollers (2 for the screw, 2 for the bottom closure) which can be adjusted independently.

The closure head is fitted with a “No cap no roll” device. The rotation speed of the head can be adjusted by means of an Inverter in order to optimize the closure and adapt it to the machine’s output.

The height of the cap distributor and the closure head are adjusted together.

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội.png) Hotline HN: +84.93 630 4626

Hotline HN: +84.93 630 4626 .png) Email: info@mnb.com.vn - Website: www.mnb.com.vn

Email: info@mnb.com.vn - Website: www.mnb.com.vn