Filling line for milk, yogurt

FLEXIBILITY easier format changeover with a wide range of products and sizes ACCURACY new PC-based architecture for easier control of machine performance and status TOP-LEVEL HYGIENE empowered solutions to preserve product integrity and guarantee the required shelf life DESIGN conceived to facilitate daily operation and reduce maintenance UPGRADABLE thanks to a modular design ready for future developments, including new carton configurations, your filling machine is sure to be up to date at any time RESOURCE EFFICIENCY simplified engineering for considerably reduced waste of resources GALDI RG270UCS has been conceived to preserve product quality throughout its required shelf life and is suitable for the filling of fresh and Extended Shelf Life (ESL) liquid foodstuff in all available carton sizes. The sturdy machine frame is 100% made in AISI 304 stainless steel and protected by full-size see-through panels, which allow operators to safely monitor the machine during operation. All parts coming into contact with the product are FCM (Food Contact Material) 1935/2004 compliant.

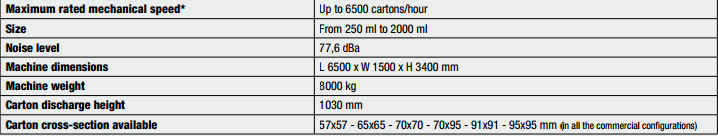

Technical features:

- PC-based control with Soft PLC and 16’’ touchscreen control panel system

- Servo driven volumetric Double Diaphragm Filler and Bottom-Up System

- Ultra-Clean System for carton decontamination with a 35% hydrogen peroxide solution

- Micro-filtered laminar airflow (HEPA filter class H14 - EN1822)

- Automatic CIP mode setting from operator panel

- Disinfection tunnel cleaning improved by rotary nozzles

- Servo-driven carton conveyor chain with torque limit software control

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội.png) Hotline HN: +84.93 630 4626

Hotline HN: +84.93 630 4626 .png) Email: info@mnb.com.vn - Website: www.mnb.com.vn

Email: info@mnb.com.vn - Website: www.mnb.com.vn