Filling line for product without carbonate

- High filling performance

- Separate air return during filling

- No size change-over for PET bottles

- User-friendly and low-maintenance

- Automatic level spout adjustment

- Product deflection inside the bottle thanks to an helical deflector

.jpg)

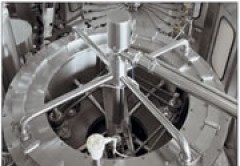

1) Filling valve

In this valve an adjustable spout is used, so there is no need to change it in case of a different bottle size.

The spouts adjustment can be either manual, manual and centralize or automatic.

The new helical deflector allows homogenous and constant filling. The liquid is spread towards the inner bottle wall to avoid foaming.

Thanks to this new deflector there is no need to change any item when changing the bottle size.

.jpg)

2) Dummy bottles

The manual dummy bottle is placed on the hanger of the lifting jack and then manually inserted and released. On request, it is possible to have automatic dummy bottle. This one is fixed on the machine and it is automatically triggered and defused by proper devices. There are no dynamic gaskets both for the manual dummy bottle and the automatic one.

.jpg)

3) Bottle lifting jack

The lifting jacks are of a pneumatic type with closed circuit, thus without any compressed air consumption. In this new pneumatic jack there is only one dynamic gasket; all the sliding movements take place on cylindrical rods. This jack arrangement allows an easy maintenance..

.jpg)

4) Product bowl

The lifting jacks are of a pneumatic type with closed circuit, thus without any compressed air consumption. In this new pneumatic jack there is only one dynamic gasket; all the sliding movements take place on cylindrical rods. This jack arrangement allows an easy maintenance.

Technical features:

- Capacity: 1500 ÷ 100.000 bph

- Number filling valves: 12 ÷ 140

- Bottles: PET

- Height of bottle : 140 ÷ 340 mm

- Diameter of bottle: (Ø) : 48 ÷ 115 mm

- Operator panel : Touch screen

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội.png) Hotline HN: +84.93 630 4626

Hotline HN: +84.93 630 4626 .png) Email: info@mnb.com.vn - Website: www.mnb.com.vn

Email: info@mnb.com.vn - Website: www.mnb.com.vn