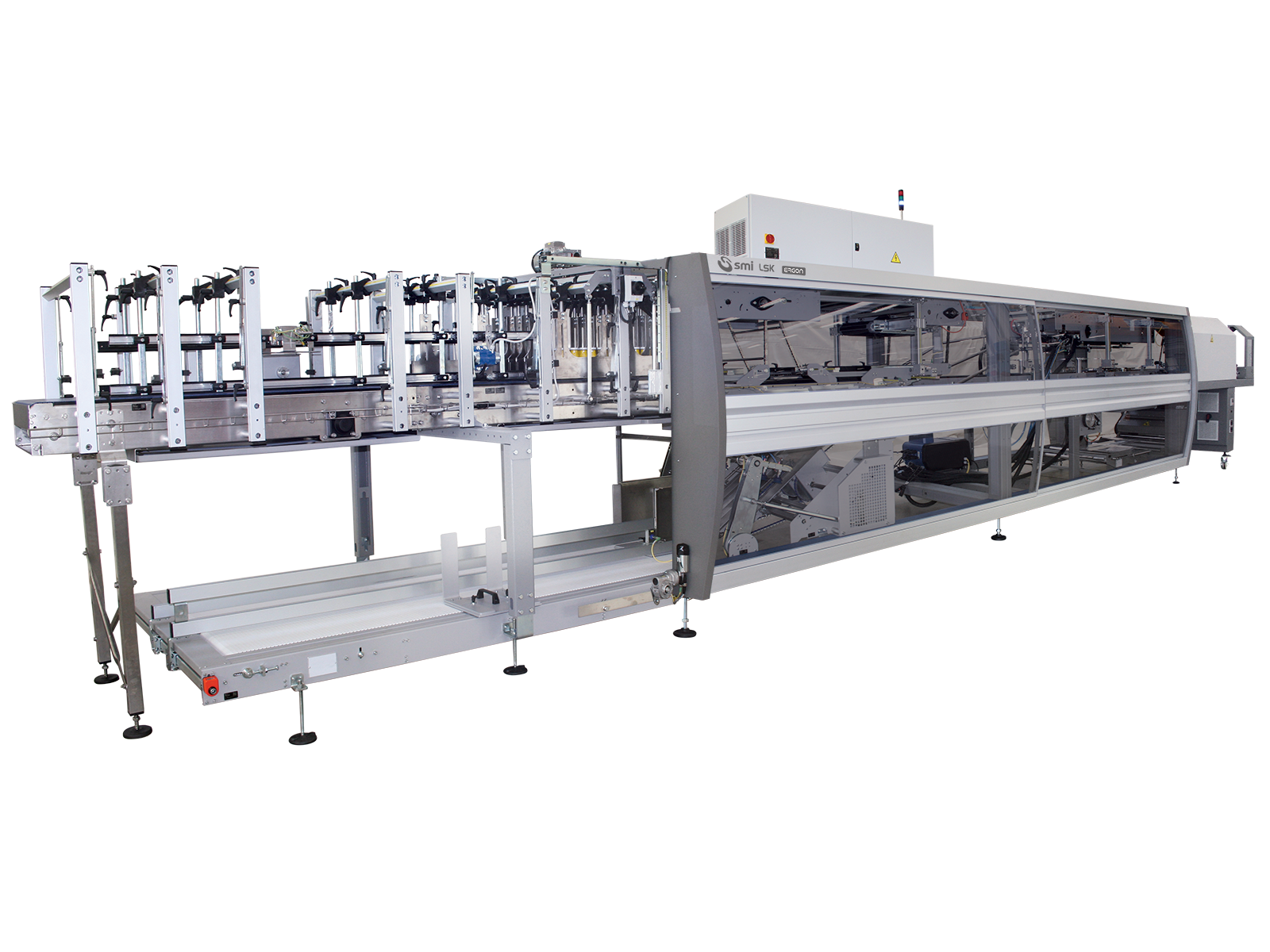

Shrinkwrappers machines

The LSK series is composed of automatic shrink wrap machines to pack plastic, metal, cardboard or glass containers. Depending on the model chosen, they can make packs in film only, cardboard pad + film, cardboard tray, cardboard tray + film.

LSK series packers achieve an output rate up to 40 packs per minute, according to the machine model and the type of product to be handled. The pack collations can vary according to the containers shape, capacity and size; the most requested collations are: 2x2, 3x2, 4x3 and 6x4.

All LSK machines are equipped with a mechanical product grouping system and are supplied with an in-line or a 90° infeed conveyour, depending on the customer’s exigencies. The change-over is manual.

Technical features:

Machine bearing frame made of sand-blasted and powder-painted steel

Standardized modules assembly

Safety sliding doors made of aluminium and trasparent guards of shock-resistant polycarbonate, which let an easy access to every section of the machine and a large visibility on the entire process of packaging.

Absence of gearboxes

For life lubricated pads

Infeed conveyor with chains made of thermoplastic material, with low friction coefficient.

Cardboard magazine situated beneath the infeed conveyour, adjustable according to the blank size

Alternate motion cardboard blank picker, equipped with suckers

Film cutting system with blade rotation

Automatic centring system for printed film provided with marks

Brush antistatic bars with carbon fibre

Machine electrical cabinet with air conditioner

The shrink tunnel features state-of-the-art technical solutions reducing energy consumption and ensuring an eco-friendly working process. The tunnel conveyor belt is made up of fibreglass bars, driven by side chains (®SMI). Thanks to the precise analysis of thermodynamic phenomena generated by the shrink process, the tunnel distributes hot air flows in an efficient and homogeneous way on the pack, thus ensuring its excellent quality at the end of the process. Shrink resistances are positioned on the side walls of the tunnel; the lubrication system is automatic and centralized (optional for SK 400 models).

Tunnel conveyour belt equipped with fibreglass bars

Heat-shrinking tunnel with forced air ventilation

POSYC® control panel mounted man-high and running the whole length of the machine

Power supply: from 380 to 480V (±5% max.) 50/60 Hz 3PH + PE

Power supply equal to 230 or 575V: with autotransformer

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội.png) Hotline HN: +84.93 630 4626

Hotline HN: +84.93 630 4626 .png) Email: info@mnb.com.vn - Website: www.mnb.com.vn

Email: info@mnb.com.vn - Website: www.mnb.com.vn