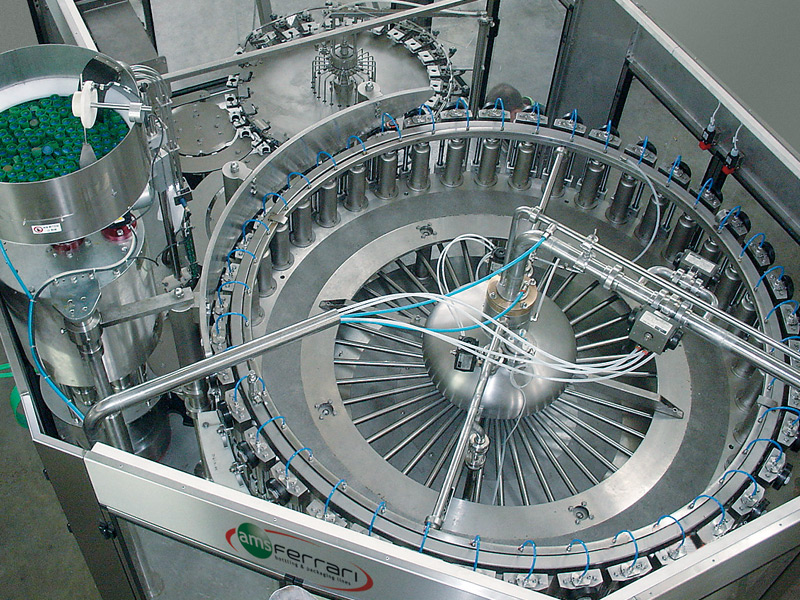

Filling line for product with carbonate 2.000 - 20.000bph

Technical features:

|

1) Innovative logic Decompression is collectorized in a single point.The breaking of a bottle automatically triggers the closing of the filling valve, thereby reducing the typical loss of product and CO2 to a minimum. |

|

2) Filling The high flow capacity filling valves are reliable, easy to disassemble and of extremely simple design. |

|

3) No more size changeover for PET bottles The bottles are conveyed at all times, during transfer from one phase to the next, by the “neck” For this reason, it is no longer necessary to replace star wheels and guides, nor to make height adjustments on all of the machines making up the filling block. |

|

4) Sanitation The tank, filling valves and other product contact parts are mirror-polished and slightly tilted to safeguard against dirt and residue and facilitate washing and draining, to be carried out using hot or cold liquid solutions. For PET machine versions, semiautomatic dummy bottles are available on request |

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội.png) Hotline HN: +84.93 630 4626

Hotline HN: +84.93 630 4626 .png) Email: info@mnb.com.vn - Website: www.mnb.com.vn

Email: info@mnb.com.vn - Website: www.mnb.com.vn