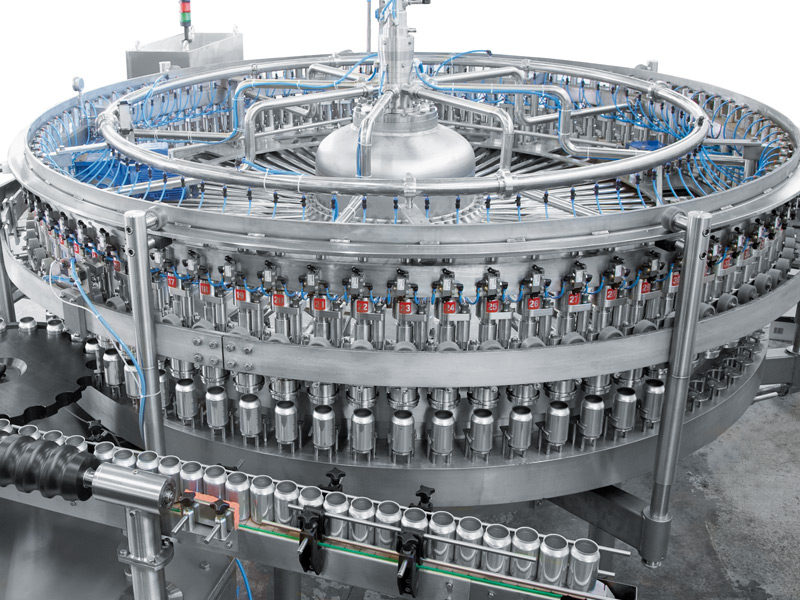

Beer can filling line

|

Can |

300 ml - 1200 ml |

|

Capacity |

2.000 – 50.000 |

1. Filling and seaming

The Central tank containing the filling product is of small dimension

- Air return in a separate pipe.

- Continuous pressure filling with absolute isobaric system.

- Return to room temperature by reduction of controlled pressure

The following features fully protect the beer from oxidation

during all phases of filling and seaming:

- The absolute absence of air in the tank that protects beer from

all danger of oxidation with an inert gas protection.

- Dual injection of inert gas in the can before filling removes

completely the air inside.

- Exit gas return in the can thru a separate pipe.

- Gas injection before seaming

Automatic machine for hermetically join the lids to the cans body for liquid products.

2. Depalletiser

The technique is the one that lift the layers “step by step” and pushe them on the accumulation table. According to specific needs, you can apply the following additional automation:

- Automatic layer removal.

- Automatic pallet stacker.

- Lineup table.

- Vacuum bridge for high speed.

3. X-Ray

The X-ray device uses x-ray technology. The device allows to detect foreign objects inside the cans. After the procedure of automatic detection, a coder ensure that the containers in question are “discarded”.

4. Tunnel drying system

Drying Tunnels are machines designed to reduce the water deposit on the walls of the filled containers, which have been previously submitted to washing, cooling and pasteurizing process. This procedure witll allow them to be duly packaged.

5. Coder

Technology for continuous inkjet prints, using a wide range of inks, expiration dates, batches, and alphanumeric text logo and barcodes. The coder offers the best compromise between performance and flexibility

6. Packaging

The shrink-wrapping machine is built with cutting-edge mechanical characteristics that allow a perfect functioning ensuring high reliability. Its compact dimensions allow and facilitate the inclusion of any machine in production line. Each machine category can produce the following type of packaging: Palletizer,Stretch wrapping machine

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội.png) Hotline HN: +84.93 630 4626

Hotline HN: +84.93 630 4626 .png) Email: info@mnb.com.vn - Website: www.mnb.com.vn

Email: info@mnb.com.vn - Website: www.mnb.com.vn