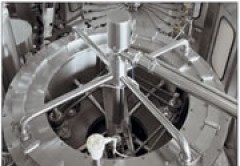

Filling line for liquid and pasty products

.jpg)

Technical features:

Linear or Rotary filler specially designed to grant the maximum flexibility and very easy cleaning procedures. It is suitable to fill liquid, semi-liquid and thick products with and without particles. Product dosing is made by means of a linear actuator controlled by brushless motor which enables the filling volume adjustment as well as the filling and product intake speeds directly from the control panel.The valves for product intake and dosing are controlled by an actuator, providing the highest filling accuracy.

.jpg)

Products: RTD, fruit juices, vegetables, teas, energy drinks etc.

Glass bottles with aluminum ROPP caps, crown cork, twist off caps.

PET bottles with plastic screw caps, sport caps, pressure plastic caps.

Neck handling for PET bottles.

Advantages:

Possibility to extend the production with different kind of bottles and caps.

High speed application with a wide range of product (high acidity, low acidity, with pulp) to satisfy the market demands

Reliable machine with easy and fast change over procedures

Hygiene.

Possible configuration with “dynamic pressurization”. The machine is fully closed and filtered air is injected into it to avoid product contamination.

Automatic or semiautomatic CIP.

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội

Address: 4/36 Nguyễn Viết Xuân, Khương Mai, Thanh Xuân, Hà nội.png) Hotline HN: +84.93 630 4626

Hotline HN: +84.93 630 4626 .png) Email: info@mnb.com.vn - Website: www.mnb.com.vn

Email: info@mnb.com.vn - Website: www.mnb.com.vn