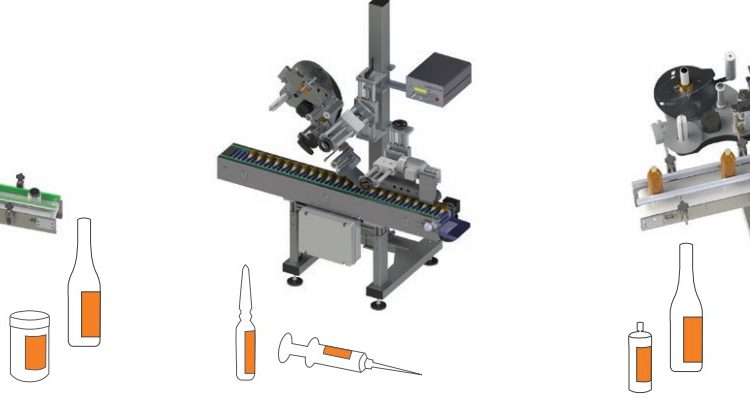

The labeling system includes a safety protection station, a pump station, and an automatic glue application and spreading station, a drying station with temperature control, a conveyor speed control with a frequency inverter, and accessory kits for one type of bottle and one type of label.

Label applicator stations can be equipped with optical positioning systems and various mechanical systems for the automatic linking of the machine.

The modular labeling machines allow for the addition of modules, facilitating future upgrades when changing the labeling position or label type.

The labeling system includes:

- Safety protection

- Automatic glue application and spreading

- One drying station with temperature control

- Manual speed control with frequency inverter

- Accessory kit for one type of bottle and one type of label

Features:

- Rotary labeling machine with fixed bottle placement positions

- Automatic label feeding, glue application, and labeling

2. The wet glue labeling machine with a capacity of 30,000 – 80,000 products/hour

Complies with CE standards, with automatic speed adjustment.

Technical features:

- Safety protection with vertical doors around the conveyor and a front entry door

- Complies with CE standards

- Automatic speed adjustment

- Frequency inverter control

- Glue rollers made of AISI 304 and glue pallet covered with rubber

- External electrical cabinet made of AISI 304, supporting temperature control

- 10” touch screen control panel mounted on a rotating frame

- PLC operation for monitoring the machine and electrical adjustments of the conveyor