- High filling speed

- Prevents air from entering during the filling process

- No need to change the filling nozzle when changing the size of PET bottles, glass bottles, etc.

- Easy operation and maintenance

- Electric filling level adjustment

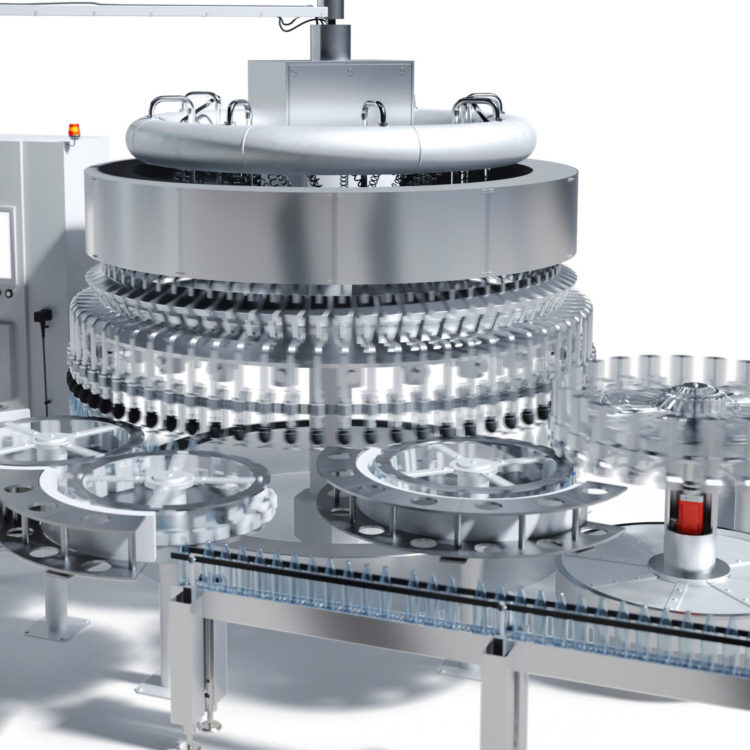

1. Filling Valve

- The nozzle of the filling valve is adjustable, so it does not need to be changed when switching to different bottle sizes.

- The nozzle adjustment can be done manually or automatically.

- The liquid is filled along the edge of the bottle to avoid foam formation.

2. Dummy bottle

The dummy bottles are designed to facilitate the cleaning process. By connecting the dummy bottles to the water discharge pipes, it prevents water from spilling onto the machine.

Upon request, the dummy bottles can be automatically controlled and will activate automatically when the cleaning process begins.

3. Bottle Lifting System

The bottle is lifted to the filling valve by the neck clamp system. The bottle lifting system operates using compressed air.

The bottle lifting system does not need to be changed when switching to different bottle sizes.

4. Product Tank

The product tank is located at the center of the machine.

All parts in contact with the product are made of AISI 304 stainless steel (which can be upgraded to AISI 316). The product tank can be cleaned from the inside.