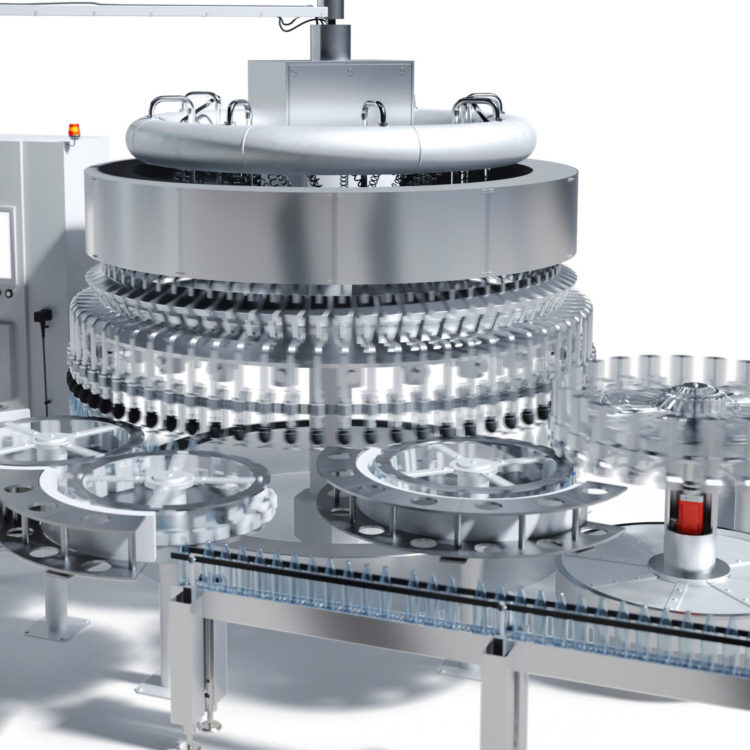

A. 2 in 1 washing and filling machine

1. Characteristics

The machine is fully automatic and independently developed using Italian technology.

This is the combination of the machine with the automatic filling technology of the “spiral gene”. The machine has the characteristics of the combined machine line and simultaneously solves the problem of factory space when using a single machine. The input and output of the machine are synchronized, the capacity is suitable, the production steps are centralized and simplified in the most convenient way. Production efficiency is increased. This machine line is suitable for automatic filling and bottling lines, especially for wine.

2. Characteristics of the washing process

1) Use elastic and strong mechanical structure to grasp bottle, overturn bottle, jar (inner washing, bottle control, overturn bottle, output etc.) The whole process is done by dynamics.

2) Continuous high efficiency adjustable capacitor, stable water jet washing, adopt frequency conversion, speed control.

4) Applying the most advanced technology in Italy has the advantage of precision, good and high precision pneumatic valves and filling valves.

5) Can replace bottles with different bottle diameters and bottle heights, and adjust conveniently.

3. Characteristics of the extraction process

(1) Wide range of bottles used: can be used with bottles of diameter 60-100mm, height 60-100mm, filling capacity can be changed conveniently.

(2) Filling height: filling level varies with different bottle types, filling level is constant with 1 bottle type.

4. Structure

| NO. | Name | Model |

Manufacturer |

Note |

| 1 | Main motor | 3KW | Huangyan Sanli | |

| 2 | Brake part | 1:40 | Huangyan Sanli | |

| 3 | Lifting motor | 0.75 | Huangyan Sanli | |

| 4 | Lifting brake | 1:60 | Huangyan Sanli | |

| 5 | Inverter | 3KW | Delta | |

| 6 | Tank | — | Harzhou | |

| 7 | Igus bearing | — | Germany-made | |

| 8 | Conveyor | High quality insulating plastic | Plastic Engineering | |

| 9 | In and out tray | High quality, insulating plastic sheet | Plastic Engineering | |

| 10 | Steel | 304 | Shanghai | |

| 11 | Protective plate | 304 | Shanghai | |

| 12 | Optical sensor | OMRON | ||

| 13 | Low voltage equipment | — | Schneider, Chint |

Specifications

|

|

Name |

Parameter |

Note |

|

|

1 |

Bottle of Pride |

High |

Depends on the customer |

|

|

Diameter |

Depends on the customer |

|||

|

Type |

Depends on the customer |

|||

|

2 |

Power supply capacity |

3KW |

|

|

|

3 |

Mass |

4t |

|

|

|

4 |

Overall size |

3000*1650*2200(L*W*H) |

|

|

|

5 |

Pneumatic pressure range |

0.6MPa-0.8MPa |

|

|

|

6 |

Gas |

<40 CBM/H |

|

|

|

7 |

Discount level |

750ml |

|

|

|

8 |

Extraction error |

±5mm |

|

|

|

9 |

Productivity |

1500-2000 B/H |

|

|

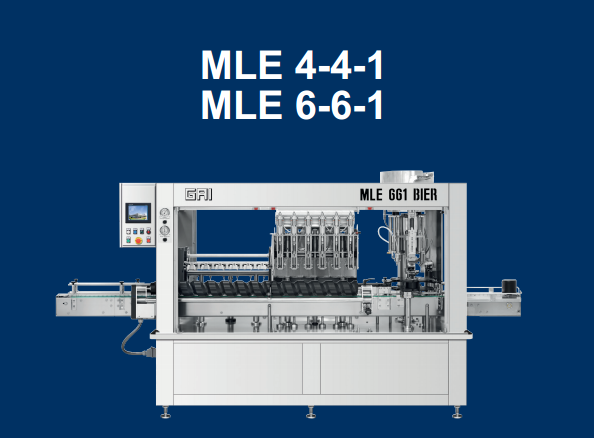

B. Single head bottle capping machine

1. Specifications

- Bottle type, height, diameter: optional

- Efficiency:≥98%

- Power supply: 220V 50HZ

- Power:≤2.5Kw

- Compressed air:0.6~0.8MPa

- Speed control: inverter

- Weight: 850KG

- Overall size: (L*W*H)2500*900*2000mm(with conveyor)

- Capacity: 30bottles/minute

2. Process

Bottles are fed in by hand-operated conveyor.

↓

Bring the bottle down under the corking head.

↓

The cork goes down the mouth of the bottle.

↓

Bottle placed under rotating head

↓

Wrap the twist knot perfectly along the spiral groove.

3. Characteristics

- Number of buttons: 01

- Load height: 850mm

- Front control screen

- Counting bottles

- Manufactured according to GMP standards

- All parts can be easily and quickly disassembled for cleaning.

- The machine is easy to control and operate.

- All settings will be displayed on the screen.

- Error detection system should be available.

- Language in English..

4. Safety

Equipment / Personnel Safety System

In accordance with applicable design and safety standards, such as ASME and/or any other standards, applicable global safety standards.

Emergency stop button. And the like should be placed in an easily accessible area.

5. Construction materials

All material of parts is stainless steel SS 304.

Non-metallic contact components, such as brushes, pads, sight glass, sensors, etc.

All gaskets must be silicone, viton or PTFE.

All electrical connections must be grounded.

6. Ingredients

| NO. | Name | Model | Brand |

| 1 | Conveyor | Plastic | YINGSHENG(Shanghai) |

| 2 | Tank cap | Stainless steel | KUIXING(Shanghai) |

| 3 | Button head | — | KUIXING(Shanghai) |

| 4 | Conveyor motor | — | ZHONGDA (NINGBO) |

| 5 | Torsion motor | — | ZHONGDA(NINGBO) |

| 6 | Sensor | E3X-NA11 | LEUZE(German) |

| 7 | PLC | — | Delta |

| 8 | Touch screen | — | Delta |

| 9 | Tripod box | SS304 | (Shanghai) |

7. Detailed images

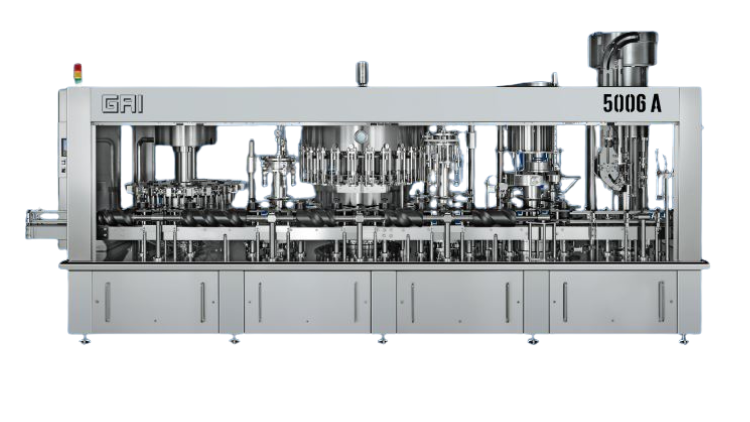

C. Corking machine

This equipment is applicable to all kinds of glass bottles, widely used for wine, fruit wine factory

1. Characteristics

Fully automatic production machine, no manual operation, saving manpower.

Plug device adopts special materials, desalination treatment cutting wire, precision and durability.

The machine is equipped with a control device, no bottle no corking, saving materials.

The machine is equipped with overload protection device, the machine will stop if the bottle is faulty, no bottle damage, no damage to the machine.

Variable frequency speed control

2. Main parameters

|

Model |

Productivity | Bottle neck type | Bottle height | Bottle mouth diameter | Electric power | Size |

|

HDZ-4 |

1500-2000(pcs/hour) | Depends on the customer | Depends on the customer

|

Depends on the customer

|

2.5KW | 1500*900*2000mm |

D. Air bottle dryer

1. Characteristics

- Using high precision air knife, with a high blowing pressure, without using condenser but using large blowing speed, no damage to the bottle.

- Use air knife friction cleaning surface, air used about 30 degrees

- No water falls into the bottle

2. Ingredients

|

NO. |

Parts name |

Model |

Supplier |

Remarks |

|

1 |

Fan |

— |

Shanghai |

|

|

2 |

bearing |

— |

Harzhou |

|

|

3 |

steel |

304 |

Shanghai |

|

|

4 |

Case |

304 |

Shanghai |

|

| 5 |

Low voltage equipment |

— |

Delixi |

|

3.Parameters

| Productivity | 2700-3500B/H |

| Bottle type | Customizable |

| Bottle height | Customizable |

| Electric power | 1.1KW |

| Dimensions (L*W*H) | 2000*720*1400mm |

E. Aluminum shrink wrapping machine

-

Characteristic

This machine is mainly suitable for corking bottles.

1) Its structure and working principle are simple, reliable and easy to maintain.

2) Motor speed is adjustable, circular heating furnace, compact structure, low power consumption, etc. Temperature control by microcomputer.

3) Anti-scald, temperature can be easily adjusted

4) Pneumatic components are all from world famous brands, reliable quality, stable working performance, saving labor and time.

2. Technical specifications

|

Model |

RS-4 |

|

Productivity |

1500-2000b/h |

|

Bottle height |

Depends on the customer |

| Diameter |

Depends on the customer |

|

Speed |

Inverter control |

|

Motor |

5kW; |

|

Size |

2000×900×1650(mm) |

F. Inspection station

1. Characteristics

1) Special lamp inspection is an important point for quality control of clear bottled wine, if not handled properly, it will lead to serious consequences.

2) When working, the bottle can clearly see the impurities and suspended substances in the bottle moving through the magnifying glass under the irradiation of the backlight, so that the detection of unqualified product leakage can be prevented.

3) Beautiful shape, easy to adjust the height; adopt imported fluorescent lamp, bright and soft light; ensure stable and harmonious spectrum. Fluorescent lamp can be adjusted according to the height of the bottle to illuminate the important parts of the product to be inspected.

2. Structure

|

NO. |

Name |

Model |

Supplier |

Remarks |

|

1 |

Fluorescent lamp |

|

Holland Philips |

|

|

2 |

Electrical equipment |

|

DELIXI |

|

|

3 |

Ball mounting structure |

|

Jiuhua |

|

G. Automatic labeling machine

- Label head diameter: ¢76mm

- Maximum label output diameter: ≤¢300mm

- Label width: according to customer

- Label height: according to customer

- Error: ±1mm

- Bottle size: according to customer

- Capacity: 1500-2000

- Power source: 220V-50Hz/60Hz (according to the customer’s requirement)

- Power: 750W

- Weight: 400Kg)

- Size: 2500mm×1300mm×1400mm(L×W×H

Image description

Labeling control by servo motor. Label wrapping speed is synchronized with conveyor speed.

Machine components:

|

N0. |

Name |

Model |

Trademark |

|

1 |

Conveyor |

— |

YINGSHENG(Shanghai) |

|

2 |

Label roller |

— |

KUIXING(Shanghai) |

|

3 |

Bottle splitter |

— |

KUIXING(Shanghai) |

|

4 |

Label Station |

— |

KUIXING(Shanghai) |

|

5 |

Bearings |

6204Z |

Japan |

|

6 |

Touch screen |

DOP-BOSS100 |

Delta(Taiwan) |

|

7 |

PLC |

14SS |

SIMENS(German) |

|

8 |

Inverter |

VFD004L21A |

Delta(Taiwan) |

|

9 |

Stepper motor |

— |

Shanghai |

|

10 |

Laminating motor |

— |

Shanghai |

|

11 |

Ice motor |

— |

— |

|

12 |

Relay |

MY2N-J |

OMRON(Japan) |

|

13 |

Sensor |

— |

LEUZE German |

|

14 |

Stainless steel |

304 |

Shanghai |

H. Ink-jet Printer

Specifications:

Number of print lines: 2-3 lines

Font size: 5×7.16×16 standard characters, 5×7.16×16 Chinese characters, 16×16 self-edit less than 16×16 arbitrariness raster

Print speed: 744 characters/s (5×7 dot raster)

Print height: 1.5-15

Print content: Expiry date, date, notes, including 50 storage information

Font: 9 sizes adjustable

Printing distance: from the top of the bottle down to a maximum distance of 30mm

Hose length: 3M

Communication connection: RS232

Ink: Available ink colors include black, blue, red etc.

Ink consumption: 600 million 5×7 characters per kg

Operating environment Temperature: 5-45 ℃

Operating environment humidity: 1% -90% RH (no dew)

Weight: 30kg

Power supply: AC220V 50HZ 100V

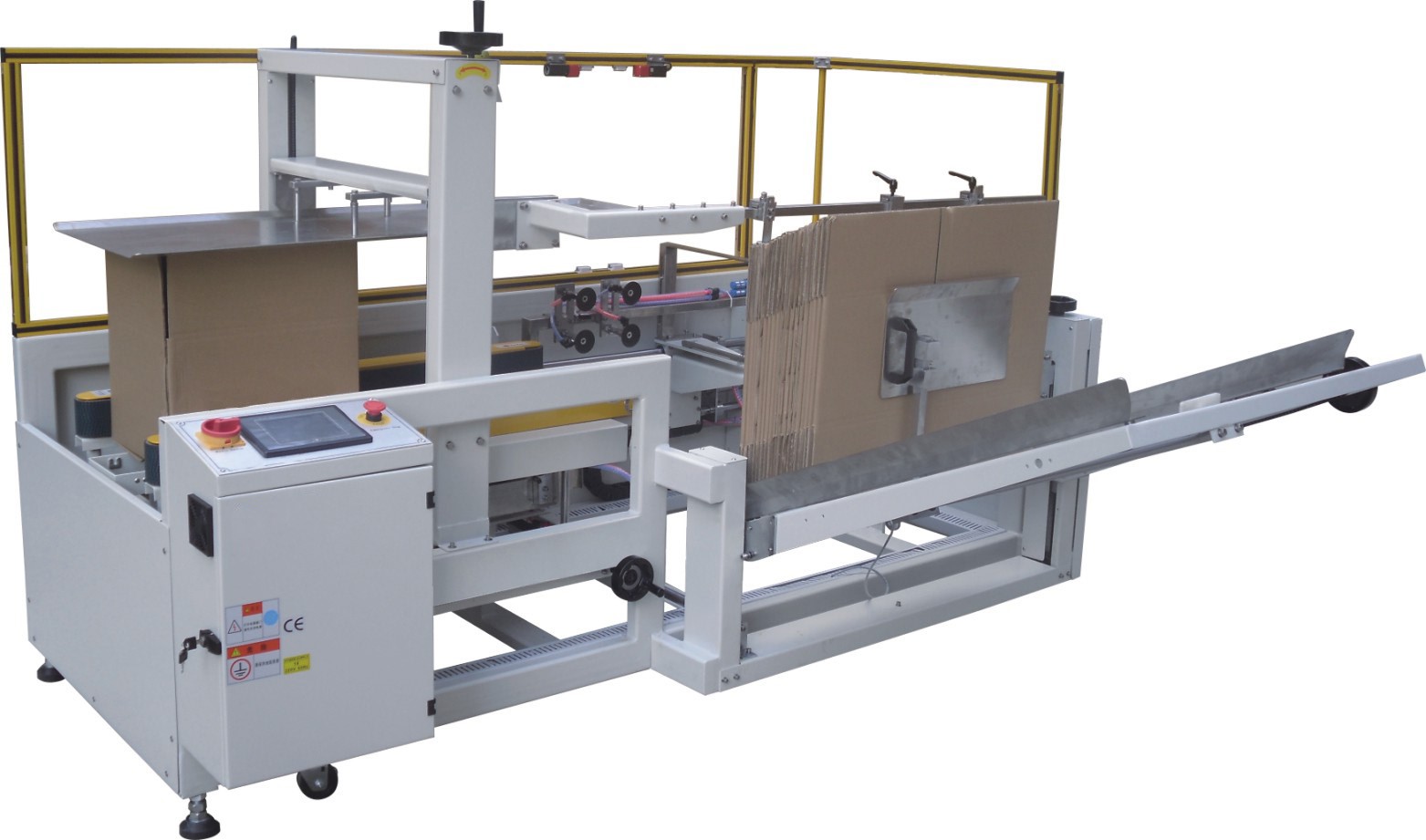

I. Automatic carton folding machine

1. Characteristics

The automatic carton folding machine can fold automatically and seal automatically. The machine adopts the Japanese OML PLC display screen control, which is very convenient for operation, management and reduces the intensity of production staff and labor. It is a necessary equipment for automatic large-scale production. Using components from Japan OMRON photoelectric sensors, the related pneumatics use Taiwan Airtac. The machine fully automatically completes opening, forming, folding, folding and tape pasting.

2. Technical specifications

|

Size |

2000 × 1900 × 1500mm |

|

Folding speed |

5-10 cartons per minute |

|

Power supply capacity |

0.75Kw |

|

Pressure of compressed air source (gas) supply |

5-6kg/cm² |

|

Box size |

L(200-500)*W(200-500)*H(100-500)mm (depending on customer requirements) |

3. Outstanding features

Fold up: automatically correct straight corners, fold the box accurately

Compact design: easy to install.

Accurate box transportation: large and small cartons, accurately place the box in the right position.

Stick the tape under: correct, thanks to the light sensor.

J. Automatic canning machine

1. Characteristics

Based on the outstanding features of various packaging machines at home and abroad, the machine is designed to adapt to the characteristics of domestic production enterprises, the newly developed automatic packaging machine has many advantages, small area, can be used on a single machine, and can also be used online with front-end packaging machines. The packaging products are diverse, various flat bottle products such as boxes or bags. This machine is widely used in medicine, food, daily chemical and other industries such as light industry.

2. Main parts of the machine

|

Size |

2300L*1300W*2000H |

Packing speed |

4-5 boxes / min |

|

Structure |

Slide rail |

Peripheral systems |

Photoelectric sensor position sensor |

|

Electrical equipment |

Taiwan Sunbang |

Optical sensor |

Omron |

|

Pneumatic equipment |

Airtac |

PLC |

OMRON, Japan |

3. Outstanding features

1) The machine is compact and takes up a small space

2) Made of steel and stainless steel material, high-end design. no burrs, sharp corners, high safety, 100% mechanical parts are produced by our own factory, quality can be controlled.

3) The machine runs stably, without friction to the product, ensuring no damage or destruction to the product.

4) Mechanical structure: transmission rail, photoelectric positioning device

K. Sealing machine

1. Specifications

| Carton size | customized |

| Compressed air source | 0.6-0.8mpa |

| Wrapping speed | 3-5 barrels/minute |

| Power supply | 220V |

| Size | L1600* W830* H1180mm |

| Seal strip width | 40mm |

2. Operating characteristics

The top cover of the carton is automatically folded, the packaging operation is smooth, beautiful and labor-saving, and it is used with the automatic packaging system. The new patented tape sticker, without using a blower to blow the tape, and the patented press device is used. Using German blades. The main transmission mechanism uses special bearings with high precision and low noise, and increases the service life of the conveyor belt

Conveyor belt, platform, speed control

- Conveyor for glass bottles

- The conveyor mainly consists of barriers, chains, sink connections.

- Use 304 stainless steel

- Chain conveyor from domestic famous brand-Huangshan, made of 2Cr13;

- Square frame, round legs, sprockets, seat bearing and other accessories are all die-cast

- The machine legs are made of stainless steel, bent with high precision.

- The tripod is connected by pin, good bearing capacity, good rigidity, and beautiful model;

- The sink is made of 1mm stainless steel plate, the trough height is 30mm, and the inner edge of the sink is made of 10mm, which can not hurt the hand and increase the steel strength. The hook of the sink is made of Φ4mm stainless steel wire.

- The transmission uses Taiwanese motor, reducer and inverter.

L. Alcohol testing stations

Equipped with a single inline bottle conveyor in the middle. The wine testing platforms used include residue and unqualified wine.

1) Made of 304 stainless steel, used for craft wine testing, bottle cleaning, gift box packing

2) Solid and reliable structure

| NO. | Name | Model |

Origin |

Note |

| 1 | Motor | 0.55KW | Huangyan Sanli | |

| 2 | Transmission brake | 1:40 | Huangyan Sanli | |

| 3 | Conveyor belt | 304 | Shanghai | |

| 4 | Table | 304 | Shanghai |