Introduction to GAI

Founded in 1946, GAI is a leading European brand specializing in manufacturing filling, capping, and labeling systems specifically designed for the wine, beer, and beverage industries. GAI’s products are renowned for their high quality, user-friendly operation, low maintenance costs, and exceptional durability, often lasting for decades. A standout feature of GAI’s machines is that nearly 100% of their components are produced and tightly controlled in-house, ensuring precision and optimal efficiency.

With stable performance and dedicated support from a team of industry-leading engineers and experts, along with a global distribution network, GAI machines consistently receive high praise from customers, earning the title of “timeless machines.”

Types of GAI Wine Filling Lines

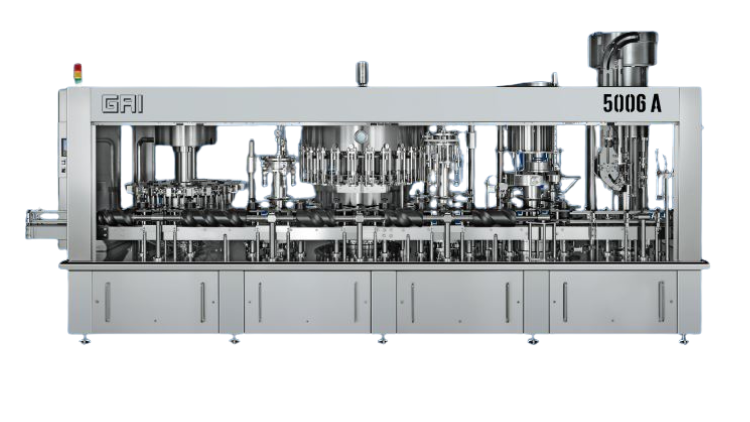

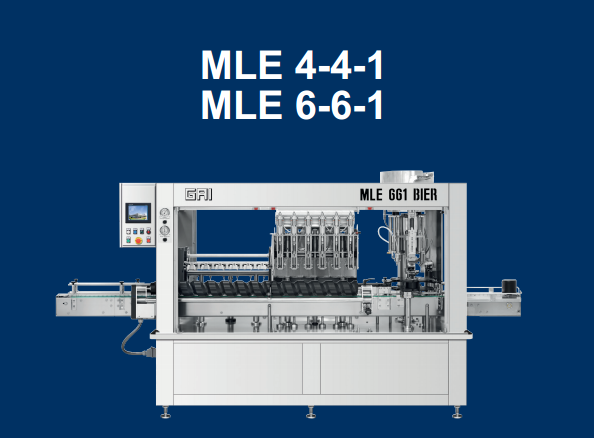

Currently, GAI’s wine filling lines are categorized into three types based on production speed:

- Capacity of 600–3,000 bottles/hour

- Capacity of 3,000–8,000 bottles/hour

- Capacity of 8,000–15,000 bottles/hour

Key Functional Units

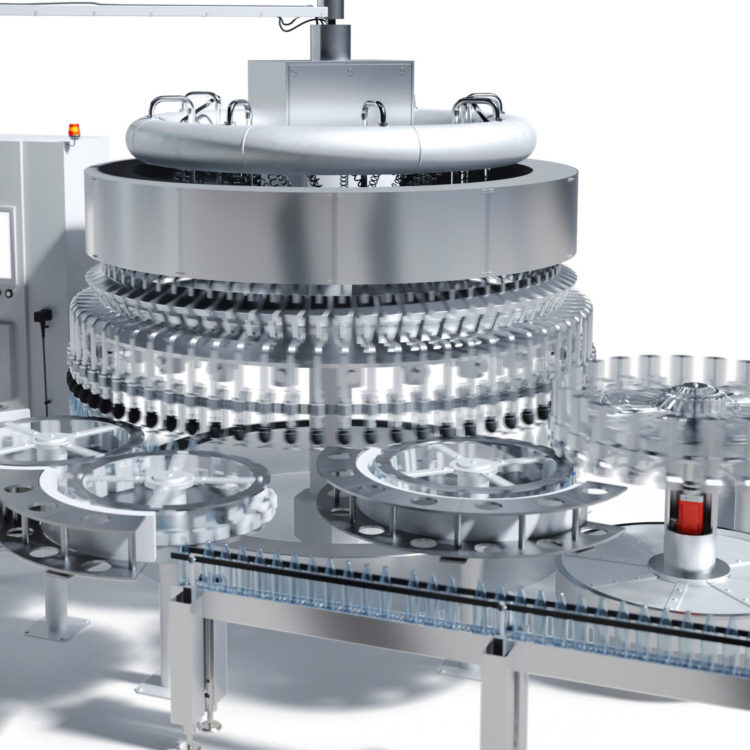

In the ‘monoblock’ wine filling lines, specific functional units ensure the filling process achieves the highest quality, preserving the wine’s original flavor. These functional units include:

1. Rinsing Section

At the start of the line, the bottle neck is securely clamped, and bottles are inverted using a system of supports and gear wheels. Spray nozzles penetrate deep into the bottles, using pressure to remove any residual particles. Customers can opt for a microfilter to sterilize the water used in this process. The rinsing water is collected and discharged through a closed-loop system, and any water remaining in the bottles after rinsing is negligible. Additionally, customers may choose an optional combination of rinsing and air-blowing systems.

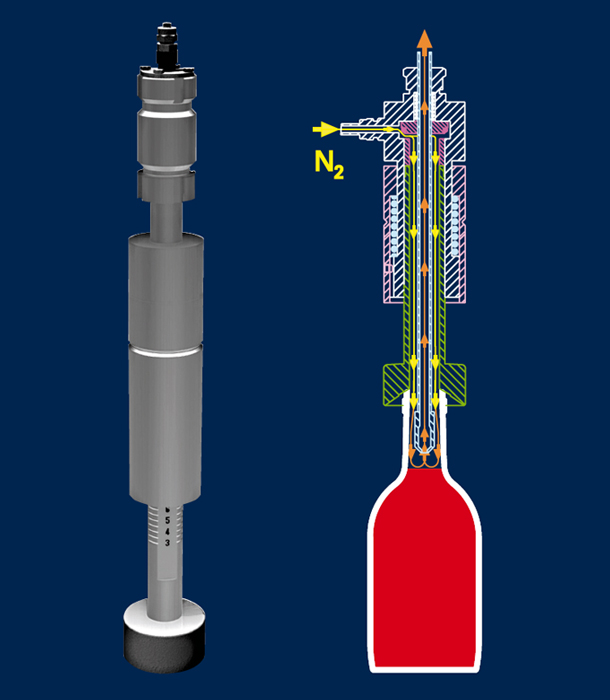

2. Vacuum and Inert Gas Injection Section

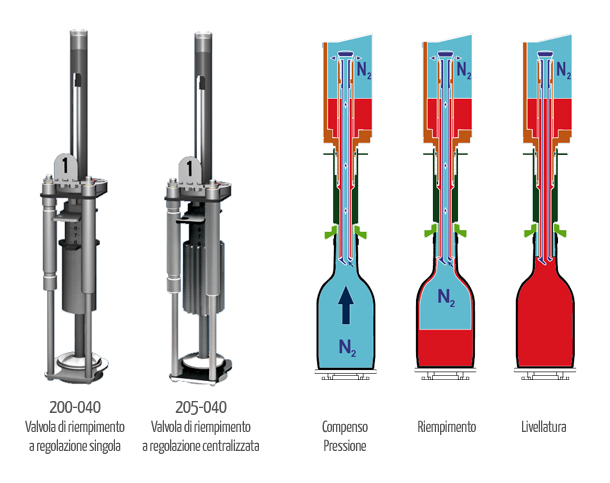

A vacuum system removes approximately 90% of the air inside the bottles. The bottles are then filled with inert gas (CO₂ and/or Nitrogen). Vacuuming and inert gas injection operate only when bottles are present. Thanks to a specially designed filling valve patented by GAI, the amount of oxygen inside the bottles is minimized, preserving the wine’s flavor and preventing oxidation.

3. Filling Section

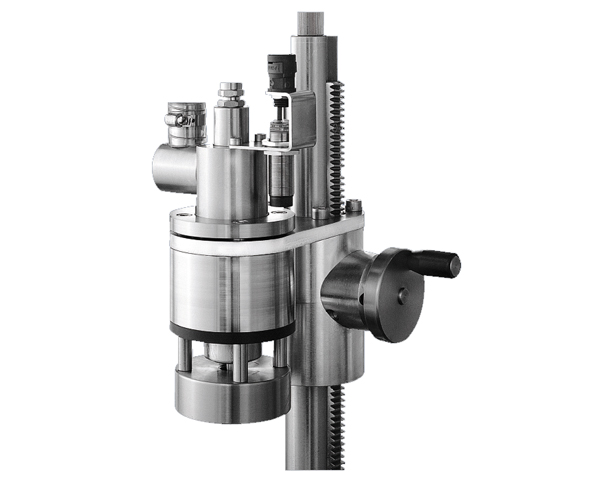

The filling section uses specialized filling valves with gentle compression and a design that minimizes dripping. These patented valves can cut off wine flow and recover any residual gases, preventing any contact between the bottle’s contents and the external environment. The valves are adjustable for sterilization purposes, and the fill level in the bottle can be precisely set from the top of the bottle’s neck. The valves have a conical shape for optimized performance.

Wine is pumped into the bottle from below, enabling the tank to be emptied naturally and completely.

The flow of wine from the tank to the nozzles is regulated by an electromagnetic valve system. For cleaning and sterilization, flow is directed from the top of the tank. The valves have an open position specifically for cleaning and sterilization purposes.

The filling tanks are designed with thick, durable materials for safety and are equipped with CE-compliant safety systems. A capacitive sensor (VEGA) with a 4–20 mA analog signal ensures efficient inverter management. A dummy bottle is used for sterilization purposes, and bottle filling processes are continuously monitored to ensure accurate filling in compliance with specifications.

4. Inert Gas Injection After Filling

This is a critical process where inert gas is injected after filling to minimize the product’s exposure to oxygen. It is also used to adjust the filling level (± 1 mm to ± 0.5 mm). Additionally, this process helps reduce the pressure between the cork and the bottle neck during the capping stage, ensuring optimal sealing and product preservation.