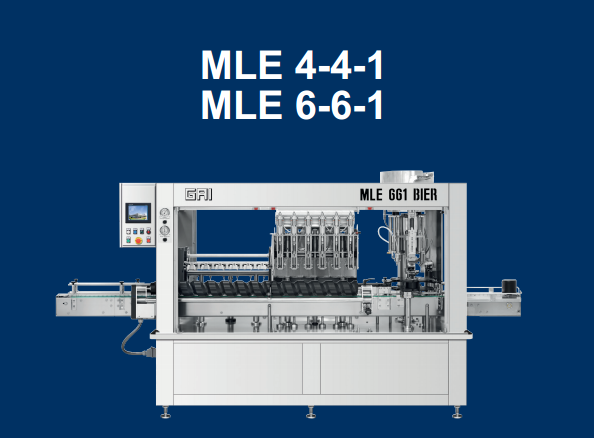

Automatic Bottle Filling Machine for Sparkling Wine (e.g., sparkling wine) made entirely of stainless steel, with 4 or 6 rinse spray nozzles, 4 or 6 filling nozzles, and a capper for corks or crown caps. The machine is designed to ensure the product achieves the highest quality by using electronically controlled pneumatic filling valves patented in 2013. It can work with both still and sparkling wines. The valves are designed to minimize oxygen levels in the bottle and optimize production speed. Furthermore, the machine can operate at high speeds even when the product temperature exceeds 5-6°C (41-43°F).

The machine components are meticulously designed by GAI engineers, from the surface to the pipe connections, and all parts use stainless steel. The user-friendly HMI screen interface allows full parameter display during operation, such as pressure and vacuum levels inside the bottle. The machine is equipped with an Ethernet port, allowing remote control and support from the manufacturer’s experts. Additionally, the company can store customer machine information in a database for easier future maintenance. GAI commits to machine quality, ensuring maximum efficiency with the lowest maintenance costs.

Features of the machine include:

- 7.5-inch touchscreen control panel

- Electric height adjustment for all filling valves

- Versatile system for various bottle sizes

- Remote control support

- Centralized filling level control

- Tank pressure control through PLC

- Sensor for detecting bottle presence

- Real-time filling time management

- Storage of filling and cleaning cycles

- Dummy bottle for cleaning

- Configured to integrate with CIP (Cleaning in Place) systems.