The growing demand for clean food in Vietnam has driven many businesses to invest in modern fruit and vegetable processing and packaging lines. MNB Vietnam is proud to be a partner providing comprehensive solutions for this industry, offering advanced equipment and systems that meet international standards.

Overview of the Fruit and Vegetable Processing and Packaging Line

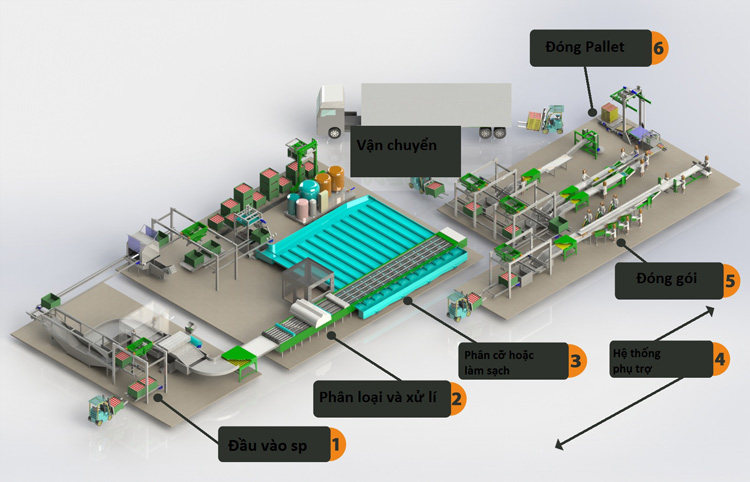

The fruit and vegetable processing and packaging line includes specialized equipment that serves the entire process, from pre-processing and treatment to packaging. The main equipment in the line includes:

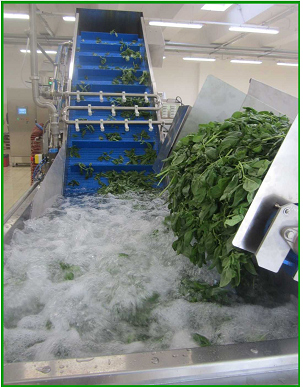

- Vegetable washing system: Completely removes impurities, ensuring food safety and hygiene.

- Pencil and dice cutting machines: Suitable for various types of vegetables and fruits, producing uniformly sized products.

- Salad mixing machine: Integrates multiple functions to quickly and efficiently prepare salads.

- Packaging system: Uses mesh bags, film wraps, or trays to preserve the freshness of products.

Market Demand and Development Trends

Currently, Vietnamese consumers are increasingly concerned with clean and safe food. Many corporations and businesses have built farms and their own cultivation systems to supply high-quality vegetables and fruits. Products like dried fruits, fruit juices, and salads are becoming more popular in restaurants and large supermarket chains.

In response to this trend, MNB Vietnam collaborates with leading European suppliers of processing and packaging systems, offering optimal solutions for food processing plants.

Machine and System Offerings

MNB Vietnam’s fruit and vegetable processing and packaging line includes:

- Washing, Sorting, and Processing System

Automatically cleans and sorts vegetables and fruits, saving time while ensuring hygiene. - Cutting and Mixing Machines

Cuts vegetables and fruits into various shapes according to processing needs.

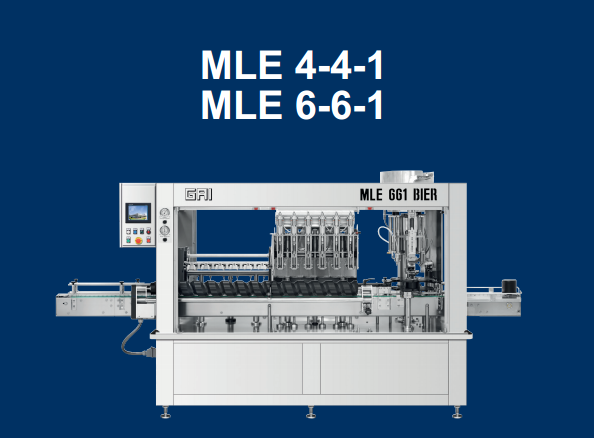

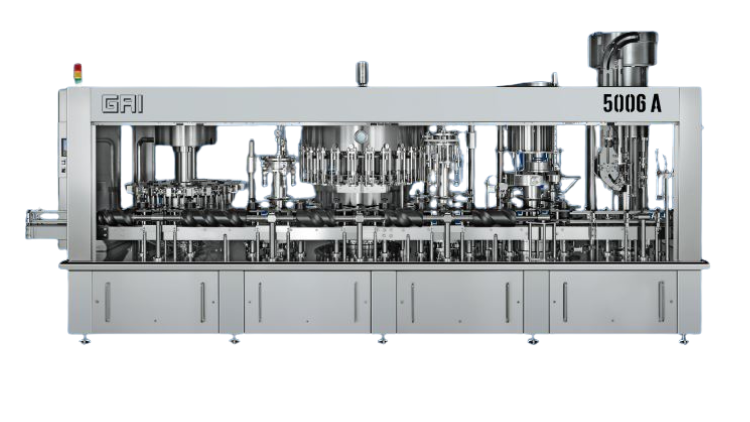

The automatic salad mixer preserves the fresh taste of the products. - Juicing and Filling Machines for Fresh Fruits

Produces high-quality fruit juice products, packed quickly and evenly. - Fruit and Vegetable Packaging Machines

Packages products in mesh bags, film wraps, or trays, tailored to each type of product. - Automatic Palletizing System

Easily arranges and transports products, optimizing the storage process. - Auxiliary Systems

- Cold storage, freezing systems: Preserves products for long periods while maintaining freshness.

- Wastewater treatment system: Meets environmental protection requirements in production.

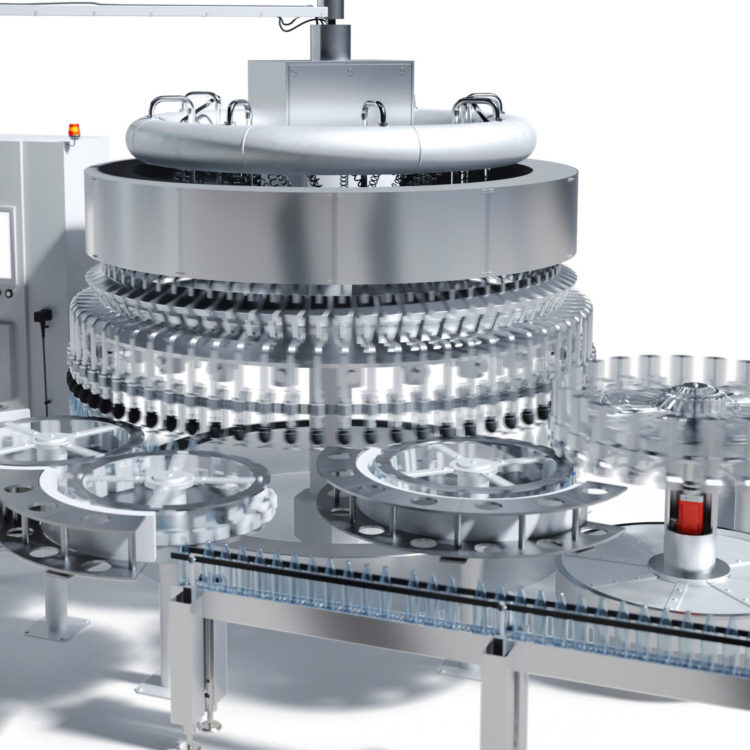

Some images of typical machines:

Benefits of Using the Fruit and Vegetable Processing and Packaging Line

- Increased Productivity and Production Efficiency

Reduces time and labor through an automated process. - Ensures Product Quality

Products meet food safety and hygiene standards, catering to market demands. - Product Diversification

Supports the processing of products such as dried fruits, salads, and fruit juices. - Reduced Operational Costs

The system is energy-efficient and optimizes the production process. - Meets Environmental Protection Requirements

Utilizes advanced wastewater treatment systems that are environmentally friendly.

Commitment of MNB Vietnam

MNB Vietnam not only provides advanced equipment and systems but also offers consulting services to provide tailored solutions for each customer’s specific needs. We are committed to:

- Ensuring product and service quality.

- Providing effective, cost-saving solutions.

- Continuously supporting businesses throughout their production and development processes.

Below is an example of a typical fruit and vegetable processing and packaging system:

MNB Vietnam’s fruit and vegetable processing and packaging line is the optimal solution for businesses looking to enhance production capacity and meet the growing demand for clean food products. With modern technology and professional services, we are ready to accompany you on your journey towards sustainable development.