Key Benefits of the CHS-6602 Carton/Box Sealing Machine

- Flexible Operation Without Pneumatic Power The machine operates without the need for pneumatic power, reducing maintenance and operating costs. This environmentally friendly design is easy to move, thanks to the lockable wheels that secure the machine in place when necessary.

- Adaptable to Various Carton Sizes Supported size range: Box length from 150mm to infinity, width and height from 110mm to 500mm.

Crank system: Quickly adjusts the width and height without the need for professional technician intervention.

The two side guide rails help secure the box during sealing, ensuring precise, alignment-free tape application. - Outstanding Performance

- Packaging Speed: Can seal up to 30 boxes per minute, with the conveyor running at a speed of 20 meters per minute.

- Maximum Load: Supports packing cartons weighing up to 30 kg, ideal for industries such as food, electronics, and consumer goods.

- Precise Sealing: The machine can use standard 2″ or 3″ tape, ensuring strong adhesion to the carton surface.

- Intelligent and Durable Design

- Premium Materials: Made from stainless steel 304, processed using modern techniques like laser cutting, edge treatment, and electroplating to ensure superior durability.

- Dual Compression Rollers: Increases tape adhesion, especially effective for non-flat cartons.

- Stainless Steel Rollers: Easy to clean and maintain, ensuring smooth operation.

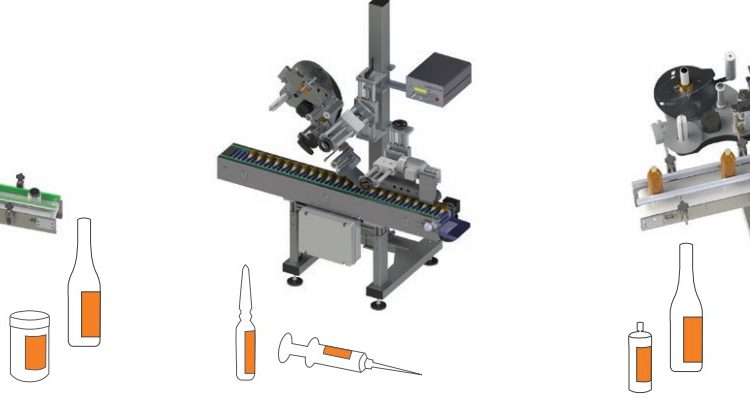

- Easy Integration with Packaging Lines The machine can be easily integrated with other packaging equipment to automate the end-of-line packaging process, including:

- Case erectors

- Case strappers

- Pallet wrappers

Additionally, the machine offers an option to attach a inkjet printer for printing barcodes or product information, along with an integrated counter to track daily productivity.