Features

- Cartons are pulled by the upper and lower belts with independent motors.

- Crank handle adjusts the width and height of cartons, making operation easy without the need for professional technicians.

- Particularly suitable for heavy, tall, or thin boxes.

- Two side guide rails.

- Can handle a load of up to 30 kg.

- No air required for machine operation.

- Stainless steel roller table for easy carton movement.

- Sealing of cartons: both top and bottom.

- Double roller compression, ensuring better sealing tightness.

- Developed and produced sealing heads, with a tape length that can be set up to 900 m (260 mm diameter).

- Double-shrink posts with padding. Adjusts carton unevenness.

- Equipped with lockable casters for easy mobility.

- Emergency stop at the tape head for quick access.

- Parts are manufactured with molds—stable quality and short delivery time.

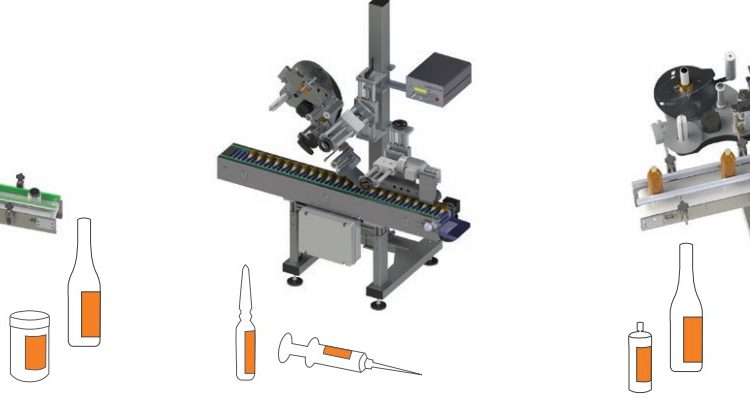

- The machine can be equipped with additional devices, e.g., 1. Labeling machine. 2. Weighing machine. 3. Inkjet printer.

- Can be integrated with carton erectors, carton strappers, or pallet wrappers for fully automated end-of-line packaging.

- Machines are designed and manufactured by us. Sturdy design with low maintenance rate.

- 90% in-house production rate, 100% made in Taiwan.

Technical Specifications

| Specification | Details |

|---|---|

| Model | CHS-6601 |

| Function | Upper and lower belt drive |

| Power Supply | 1 phase, 110/220/240 V |

| Belt Width | 2″ or 3″ |

| Carton Size for 2″ Tape | Length: 150~∞mm, Width: 110 |

| Carton Size for 3″ Tape | Length: 150~∞mm, Width: 135 |

| Overlap Tape | L: 60±5 mm (standard) |

| Working Height | 570-770 mm |

| Conveyor Speed | 20 m/min |

| Control System | Traditional distribution system |

| Capacity | 30 cartons/min (Data for carton length = 330 mm) |

| Machine Dimensions | Length: 1,100 mm, Width: 790 mm, Height: 1,420 mm |

Note: Actual performance depends on carton size and operator efficiency.

Options

- Mechanical and electromechanical options:

- Custom sizes for special cartons.

- 1.5″ tape head for 1.5″ tape width.

- External diameter of OPP tape: 350 mm.

- Overlap tape 70±5 mm.

- Extended roller table L: 500 mm x W: 500 mm / Roller conveyor L: 750 mm x W: 500 mm for packaging box in/out.

- Tape head and NG tape sensor with alarm.

- Power supply: 3-phase, 220/380/415/440 V.

- PLC control system. Integration with carton erectors, carton strappers, or pallet wrappers for end-of-line automation.

- Mechanical counter.

- Add a top folding mechanism and support for top flap closure before sealing.

- CE certified.

- Acrylic or swing-out steel protective mesh with a safety switch.

Special Requirements and Custom Designs Available