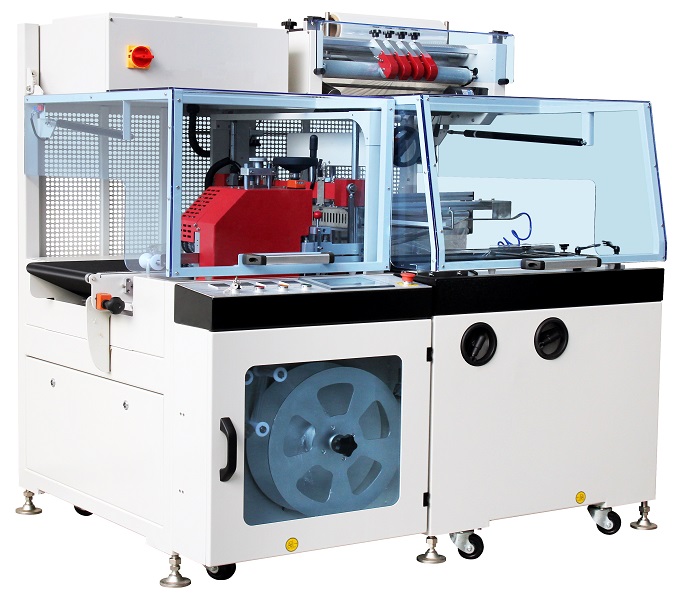

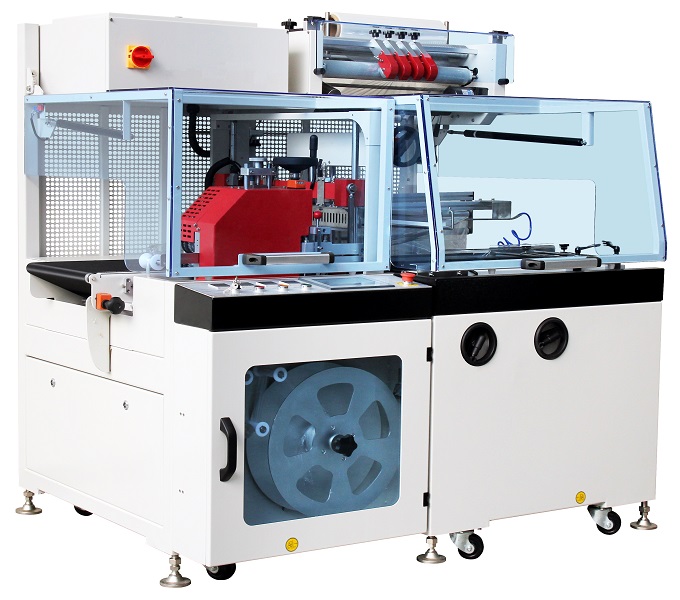

The shrink film cutting machine is a device designed to cut shrink film into sections that are appropriately sized for the products to be packaged. The machine automatically cuts, seals, wraps, and shrinks the film around the product. When the machine is in operation, the product moves along a conveyor belt to the shrink film section. Once the product arrives, a cutting blade adjusts the film to fit the product size. Subsequently, the heating unit helps shrink the film, tightly enclosing the product, creating a protective wrap that helps preserve the product.

The machine consists of two main parts: the shrink film cutting machine and the shrink tunnel.

The automatic shrink film packaging machine is suitable for fully automatic shrink wrapping. The horizontal cutting blade uses a vertical shaft bearing, while the vertical cutting blade uses a heat-sealing blade with constant temperature control. The film is then folded and sealed on three sides.

The shrink tunnel uses a dual circulation hot air system, with a high-power fan turbine that helps the tunnel heat up quickly, providing a large and uniform airflow. The conveyor motor uses an infinitely variable speed motor, which ensures high durability and low noise. Based on the product size, the conveyor speed and tunnel temperature can be adjusted to achieve optimal shrink wrapping results.